Do I Need To Cook The Meat Before Or After I Dehydrate It

Jerky and Food Condom

When raw meat or poultry is dehydrated at dwelling - either in a warm oven or a food dehydrator - to brand jerky which volition be stored on the shelf, pathogenic bacteria are probable to survive the dry out heat of a warm oven and peculiarly the 130 to 140 °F of a food dehydrator. Included hither is the scientific background behind drying food to make information technology safe and the safest procedure to follow when making homemade jerky.

What is hasty?

This product is a nutrient-dense meat that has been made lightweight past drying. A pound of meat or poultry weighs about four ounces after being made into jerky. Considering almost of the moisture is removed, it is shelf stable - tin be stored without refrigeration - making it a handy food for backpackers and others who don't take access to refrigerators.

Hasty is a nutrient known at least since ancient Egypt. Humans made jerky from creature meat that was as well big to swallow all at once, such as carry, buffalo, or whales. North American Indians mixed basis dried meat with dried fruit or suet to make "pemmican." "Biltong" is dried meat or game used in many African countries. Our word "hasty" came from the Castilian word "charque."

How can drying meat make it rubber?

Drying is the world's oldest and virtually common method of nutrient preservation. Canning technology is less than 200 years onetime and freezing became practical just during this century when electricity became more and more than available to people. Drying technology is both unproblematic and readily available to most of the world'due south culture.

The scientific principal of preserving food by drying is that by removing moisture, enzymes cannot efficiently contact or react with the food. Whether these enzymes are bacterial, fungal, or naturally occurring autolytic enzymes from the raw food, preventing this enzymatic activity preserves the food from biological action.

What are the types of nutrient drying?

There are several types of food drying. Two types of natural drying - sun drying and "adibatic" (shade) drying - occur in open up air. Adibatic drying occurs without rut. Solar drying sometimes takes identify in a special container that catches and captures the sun's estrus. These types of drying are used mainly for fruits such every bit apricots, tomatoes, and grapes (to make raisins). Sun drying is not recommended for making meat jerky due to a lack of a steady heat source and the potential for contagion from animals, insects, grit, and leaner.

Drying from an bogus heat source is washed past placing nutrient in either a warm oven or a food dehydrator. The main components of an electric food dehydrator include:

- a source of heat;

- air flow to circulate the dry out air;

- trays to hold the food during the drying procedure; and

- mesh or leather sheets to dry out certain types of foods.

Why is temperature important when making jerky?

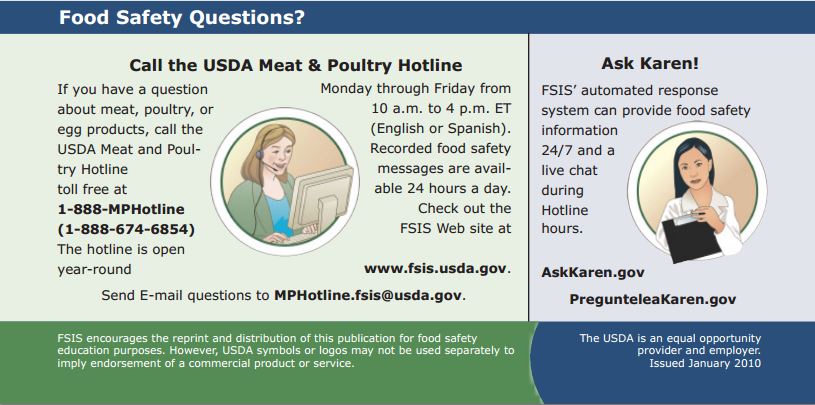

Illnesses due to Salmonella and E. coli O157:H7 from bootleg hasty raise questions near the safety of traditional drying methods for making beef and venison jerky. The USDA Meat and Poultry Hotline's current recommendation for making jerky safely is to heat meat to 160 °F and poultry to 165 °F before the dehydrating process. This step assures that whatsoever bacteria nowadays will be destroyed by wet heat. Just most dehydrator instructions do not include this pace, and a dehydrator may not achieve temperatures high plenty to heat meat to 160 °F or 165 °F.

Later on heating to 160 °F or 165 °F, maintaining a constant dehydrator temperature of 130 to 140 °F during the drying process is important considering:

- the procedure must be fast plenty to dry food before information technology spoils; and

- it must remove enough water that microorganisms are unable to grow.

Why is information technology a food safety concern to dry meat without get-go heating information technology to 160 °F?

The danger in dehydrating meat and poultry without cooking it to a safe temperature first is that the appliance will non estrus the meat to 160 °F - a temperature at which leaner are destroyed - before it dries. After drying, bacteria get much more heat resistant.

Within a dehydrator or low-temperature oven, evaporating wet absorbs almost of the estrus. Thus, the meat itself does not begin to rise in temperature until most of the wet has evaporated. Therefore, when the dried meat temperature finally begins to ascent, the leaner have get more rut resistant and are more likely to survive. If these surviving bacteria are pathogenic, they can cause foodborne disease to those consuming the jerky.

What research findings be on the rubber of jerky?

"Effects of Preparation Methods on the Microbiological Safety of Home-Dried Meat Jerky" was published in the Periodical of Nutrient Protection, Vol. 67, No. 10, 2004, Pages 2337–2341. The authors are from the University of Georgia (Brian A. Nummer, Judy A. Harrison, and Elizabeth L. Andress, Section of Foods and Nutrition, and Mark A. Harrison, Department of Nutrient Science and Engineering science) and from Colorado State University (Patricia Kendall, Department of Food Science and Human Nutrition and John N. Sofos, Department of Animal Sciences ).

Marinating meat doesn't make raw meat rubber. "Marination lone did non issue in significant reduction of the pathogen compared with whole beef slices that were non marinated," concluded the report.

In the jerky studies, some samples showed full bacterial destruction and other samples showed some bacterial survival — especially the jerky fabricated with ground beef. Further experiments with lab-inoculated venison showed that pathogenic E. coli could survive drying times of up to x hours and temperatures of upwardly to 145 °F.

A written report by the Harrisons and Ruth Ann Rose, also with the Academy of Georgia, was published in the January 1998 Journal of Food Protection, Vol. 61, No. 1. The authors analyzed ground beef jerky fabricated with a commercial beef jerky spice mixture with and without a curing mix containing salt and sodium nitrite.

Half of the ground beef was inoculated with E. coli O157:H7 before making it into hasty strips and dehydrating it. The authors found that in both the heated and unheated samples, the hasty made with the curing mix had greater devastation of bacteria than jerky made without it. The jerky made with the mix and heated before dehydrating had the highest destruction charge per unit of bacteria.

They concluded, "For ground beef jerky prepared at home, safety concerns related to E. coli O157:H7 are minimized if the meat is precooked to 160 °F prior to drying."

What are the USDA Meat and Poultry Hotline'south recommendations for making homemade hasty?

Research findings support what the Hotline has been recommending to callers. Additionally, safe handling and training methods must ever be used, including:

- E'er wash hands thoroughly with soap and water before and later on working with meat products.

- Employ clean equipment and utensils.

- Keep meat and poultry refrigerated at 40 °F or slightly beneath; use or freeze basis beef and poultry inside 2 days; whole reddish meats, inside iii to 5 days.

- Defrost frozen meat in the fridge, not on the kitchen counter.

- Marinate meat in the fridge. Don't save marinade to reuse. Marinades are used to tenderize and flavor the jerky before dehydrating it.

- Steam or roast meat and poultry to 160 °F as measured with a meat thermometer before dehydrating it.

- Dry meats in a nutrient dehydrator that has an adjustable temperature dial and volition maintain a temperature of at to the lowest degree 130 to 140 °F throughout the drying process.

Are there special considerations for wild game jerky?

Yeah, there are other special considerations when making homemade jerky from venison or other wild game. According to Keene and his co-authors, "Venison tin can be heavily contaminated with fecal bacteria -- the degree varying with the hunter's skill, wound location, and other factors. While fresh beef is unremarkably speedily chilled, deer carcasses are typically held at ambient temperatures, potentially allowing bacteria multiplication."

Is commercially made jerky safe?

Yes, the process is monitored in federally inspected plants by inspectors of the U.Due south. Department of Agronomics'southward Food Safe and Inspection Service. Products may exist cured or uncured, dried, and may be smoked or unsmoked, air or oven dried. The following terms may be on processed jerky products:

- "Beef Jerky" - produced from a single piece of beef.

- "Beef Hasty Chunked and Formed" - produced from chunks of meat that are molded and formed, so cutting into strips.

- "Beef Jerky Footing and Formed or Chopped and Formed" - produced from basis or chopped meat, molded and cut into strips. Beef Jerky containing binders or extenders must show true production proper noun (due east.g., "Beef and Soy Protein Concentrate Jerky, Ground and Formed").

- "Species (or Kind) Jerky Sausage" - the production has been chopped and may be dried at any stage of the process, and information technology is stuffed into casings.

What is the safe storage fourth dimension for hasty?

Commercially packaged jerky can be kept 12 months; home-dried jerky can be stored one to 2 months.

Impress the complete USDA Fact Sheet on Jerky Nutrient Condom here.

* Attribution cited as follows: U.Due south. Section of Agriculture.

Do I Need To Cook The Meat Before Or After I Dehydrate It,

Source: https://www.lemproducts.com/jerky-food-safety

Posted by: MillerConfled.blogspot.com

0 Response to "Do I Need To Cook The Meat Before Or After I Dehydrate It"

Post a Comment